So, every now and then, often at the pub and / or late at night when everyone’s tired, conversations happen that are either weird or surreal or, more often than not, both.

Such conversations include things like ‘who would win in a fight between spacemen and ninjas’ and ‘who should play such and such a character from my favourite book’. They nearly always devolve into further nonsense and have been known to elicit arguments leading to people not speaking to each other for several minutes at a time.

Despite all that, they’re still nowhere near as divisive as Monopoly.

Anyway, one recent discussion, and one which even has a tenuous (very, very tenuous) link to the construction industry, is the eternal:

How feasible is it to build the Death Star?

It’s a question that has also weighed heavy upon the denizens of the internet, although, as one such denizen, I can confirm that we’re also weighed heavily upon by pictures of cute animals, videos of cats with their heads stuck in cups, and discussions of the finer points of colour theory.

Back on topic, it weighed upon people so heavily that in 2012 a petition with over 34,000 signatures was sent to the White House asking them to consider building a Death Star.

No, really. It even made BBC News !

Fortunately (or unfortunately, depending on your point of view) the White House was forced to concede that there were no plans to build a Death Star, nor was there likely to ever be any such plans. The official response from the White House is hilarious and surprisingly well thought out and can be read in full here on Wired.com .

I’m not even going to allow myself to consider how different the response would have been from the Trump Administration.

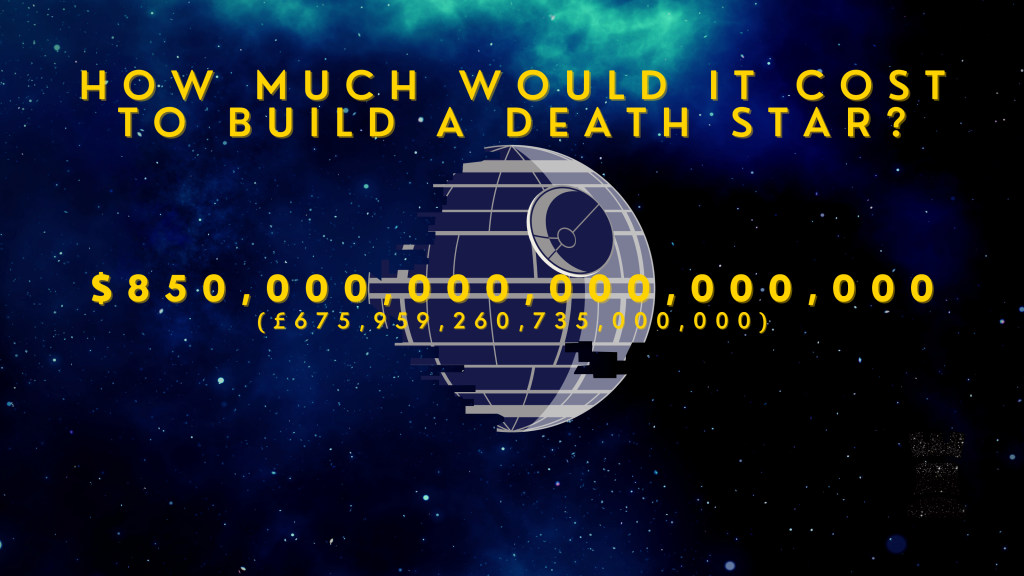

What would a Death Star even cost?

The estimated price alone would surely put most nations off the idea of building something as astronomically (heh) expensive as the Death Star, because the estimated cost put forward by the White House is in excess of $850,000,000,000,000,000. That’s eight hundred and fifty quadrillion dollars, which is an amount of money that even my limited knowledge of economics says is going to be hard for a planet to scrape together, let alone a single county.

It does though raise interesting questions about the economy of the Galactic Empire and their movement of materials and goods before you even get onto the technology required to move a giant metal football through space.

And how long would it even take to build?

On to the subject of materials, it’s estimated that it would take 830,000 years at current global output levels to produce the amount of steel needed for just the superstructure of the Death Star.

I mean, steel probably isn’t the best option for building space craft anyway considering its strength vs its mass, and surely you’d go for something like ceramics or carbon fibre or even aluminium like they used in the space shuttles, but that’s beside the point.

Then you’ve got to get all that metal into space, along with all the infrastructure for putting it together, and then you’ve got to keep it all in a consistent geostationary orbit, which even my (admittedly basic) grasp of physics says is going to require its own infrastructure and fuel supply.

So, let’s assume that to get past that issue, you build it in open space. There’s plenty of that around even within our solar system. You could even wrangle a handy asteroid or two to mine for minerals and resources for the building project (as discussed on Space.com ). You’d then still have to account for how you’re going to protect everything against solar radiation and space debris, how to get your workforce to and from the infrastructure, and the little things like how to shield the giant laser so it doesn’t kill everyone within the Death Star.

Then, then, assuming that you happen to have a spare planet or three’s entire GDP lying around next to your conveniently placed asteroids, you still need to think about running costs.

Speaking of Running Costs…

My handy Haynes Manual (yes I’m that much of a nerd, also my parents are awesome) tells me that the Death Star operates with a population of around 1.2 million people, though other equally nerdy estimates put this closer to 2.1 million people.

Carrying enough consumables to feed that population, plus all the people, superstructure, armour, engines, guns and the whopping great laser system puts the estimated weight of the Death Star at around 900 trillion tonnes.

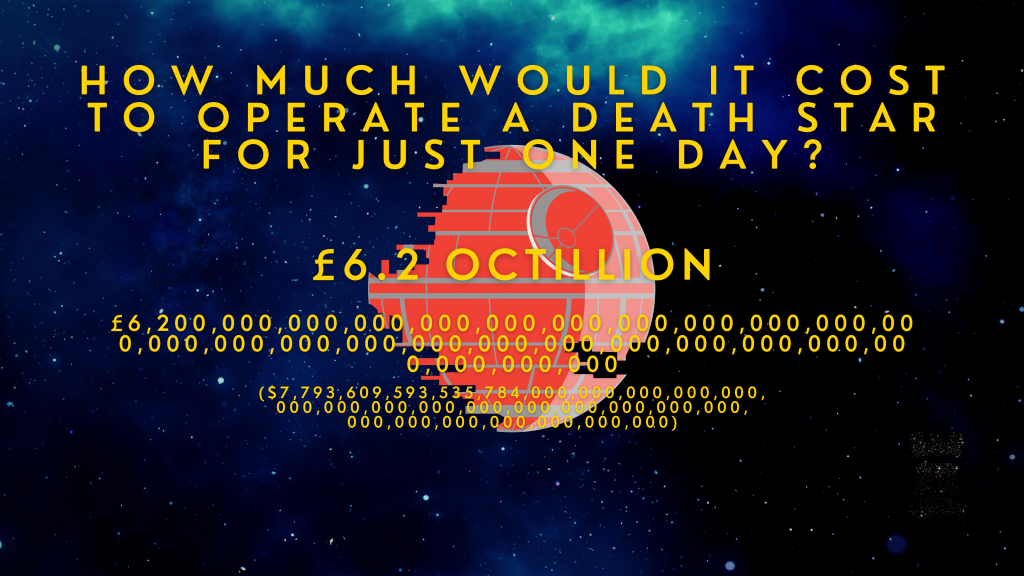

Ovo energy calculated, in an admittedly fast and loose fashion, that the cost of pushing all that weight through space, firing and charging the laser and keeping the crew going for just one day would be in the region of £6.2 OCTILLION!!

TL;DR

I suppose that what this really boils down to is, to paraphrase a quote from another famous movie, just because you can do something it doesn’t necessarily mean that you should. Or rather, just because you can theoretically do something, it doesn’t mean that you can actually afford it.

No matter how cool you might think the Death Star is or how much of the strength of humanity it might prove to the hollow remains of the bacteria that once lived on Mars, the Death Star is (currently) an impossibility at the size shown in the movies from the point of view of cost, materials and technology.

That said, 54 years ago we landed a man on the moon using a computer with considerably less processing power than my mobile phone, so I suppose anything could be possible in another 54 years.

So long as you remember to shield the exhaust ports.

Disclaimer:

- This post is not an endorsement of Ovo Energy, the White House or building your own Death Star.

- The author has no legal rights or ownership to the Death Star, now owned by Disney, nor does she endorse world or galactic domination.

- That said, all model Death Stars will be gratefully received and zoomed around the office complete with pew pew noises, because the author is not so secretly still a 12 year old at heart.

- And on one last note, yes, there really is a Haynes Manual for the Imperial Death Star DS-1 Orbital Battle Station.